INNOVATIVE PROJECTS PLATFORM

Technology

The natural gas industry in and around Europe is going through a period of unprecedented change. Investment into R&D pilot and demonstration projects is essential as it creates the opportunity for new and improved technologies, which are vital in enabling the transition to decarbonization of the gas sector. ENTSOG Members (TSOs) are developing new and innovative technologies to offer sustainable solutions for the gas sector. These technologies focus on optimization of the grid usage, creation of digital layer connections and support decarbonization of the EU gas system. Please find specific examples in the list provided below.

GRTGaz

West Grid Synergy

In western France West Grid Synergy aims to design and experiment smart grid solutions to maximise biomethane injection into the transmission and distribution systems. This project essentially inaugurated the first reverse flow of locally produced biomethane from distribution to transmission in France.

Contact: jeanmarc.brimont@grtgaz.com

CREOS

SMARTY

Creos is making extensive investments in its natural gas networks. SMARTY is a new smart gas meter which measures the gas consumption in each home. Whether via customer's wired or wireless gas meter, the meter data is always transferred to your smart electricity meter and then, via the existing electricity network, to the central system managed by Luxmetering and finally to the gas supplier. This process is referred to as communication via power line carriers.

Contact: yves.reckinger@creos.net

Ontras

Energy Park at BAD LAUCHSTÄDT

Hydrogen is produced by a 35 MW electrolyser, which is directly connected to a wind farm. The pure hydrogen is stored in a nearby salt cavern. The transport between the underground storage and the end users for the hydrogen inside an existing industrial area is provided by a converted natural gas pipeline.

Contact: Eric.Tamaske@ontras.com

SNAM RETE GAS S.P.A.

Testing of the H2NG supply in Contursi Terme

Snam has launched its experiment of introducing a 5% hydrogen and natural gas blend into the Italian gas transmission network. The experiment, the first of its kind in Europe, is being conducted in Contursi Terme, and involves the supply of H2NG (a blend of hydrogen and gas) to two industrial companies in the area: a pasta factory and a mineral water bottling company.

Contact: dina.lanzi@snam.it

Gaz-System

HESTOR- Energy storage in the form of hydrogen in salt caverns

The aim of the HESTOR research and development project carried out by a scientific and industrial consortium was to investigate the possibility of hydrogen storage in salt caverns, generated from RES, and its further use for energy generation and technological purposes in oil & refinery industry. The Project also considered technical and economic aspects of the use of hydrogen as a fuel in transport. Read more about the other issues addressed in the document using the link below.

Contact: dorota.polak@gaz-system.pl

Ontras Gastransport GmbH, SNAM Rete Gas S.p.A.

Linz Hydrogen Initiative

Austrian Presidency of the EU Council started the “Linz Hydrogen Initiative” and invited to a high level conference on the eve of the Informal Meeting of the Energy Ministers on 17 September. The conference focused on the topics of renewable hydrogen, energy storage technologies and innovative energy technologies for energy intensive industries.

Contact: ina.adler@ontras.com, dina.lanzi@snam.it

Enagás S.A.

RenovaGas

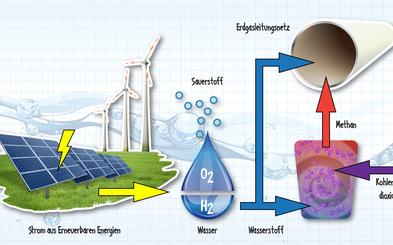

RENOVAGAS is a research project whose first phase finished in 2017. It first aim was the development of a 15 kW demonstration plant for the production of synthetic natural gas (SNG) from the electrolytic production of hydrogen with renewable energy sources (RES) and its combination directly with a biogas stream, that is, without separating CO2 from the methane, through a methanation process, so the synthetic natural gas obtained was fully renewable.

Contact: jrubio@enagas.es

Ontras Gastransport GmbH

MoBIO 800

ONTRAS in cooperation with the NEUMAN & ESSER Group, developed a mobile biogas compressor. This compressor not only avoids expensive downtime at injection plants, it also enables redirection of pipeline gas during maintenance work. This helps ONTRAS to minimize flare-off emissions. Also, in case of a failure or malfunction in a stationary system, it should be possible to connect and use the mobile solution in the short-term.

Contact: ralf.borschinsky@ontras.com

National Grid Gas

Project GRAID

National Grid's robotic inspection device GRAID can inspect the inside of live, high-pressure gas pipelines, up to 100 bar(g) and provide reliable condition data on our critical assets. This technological leap will allow NGGT to cut asset maintenance costs by eliminating unnecessary excavations and providing data to allow asset life extension. It will also generate potential carbon savings of more than 2,000 tonnes annually, equivalent to the emissions from almost 500 UK households. It is a critical benefit as we move towards a low-carbon economy. In addition, National Grid are open and willing to discuss collaboration projects with any interested TSOs.

Contact: David.Hardman@nationalgrid.com

Gas Connect Austria GmbH

Wind2hydrogen

The Wind2Hydrogen pilot facility in Auersthal, Lower Austria was in operation from January 2014 until the end of 2017. It converted power from wind turbines into transportable, storable hydrogen using a new, specially developed electrolysis process that responds very quickly to changing loads from a wind farm, and can economically produce high pressure of around 165 bar.

Contact: robert.paulnsteiner@gasconnect.at