INNOVATIVE PROJECTS PLATFORM

Hydrogen

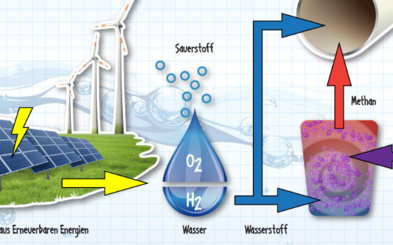

Hydrogen can be produced by various process technologies. Hydrogen can be obtained from natural gas through a steam reforming process or a methane pyrolysis process; produced by splitting water into hydrogen and oxygen via electrolysis or via gasification process, by converting solid fuel (coal or woody biomass) to hydrogen. Hydrogen can also by produced through anaerobic digestion, converting wet biomass to hydrogen. Hydrogen can be utilised directly as fuel or, depending on the application, blended with natural gas.

Hydrogen production from RES-based electricity in power-to-gas facilities or from other fuels in combination with CCS contributes to the decarbonisation of the energy system.

OGE, GRTGaz, SNAM, Terega, Enagas

HyDeal

HyDeal is to enable hydrogen transport from Spain to France and, in a second step, to Germany. It aims for expansion with production in Tunisia and Italy, and transport via Italy.

Gas Connect Austria

Wind2Hydrogen Auersthal

The Wind2Hydrogen pilot facility in Auersthal, Lower Austria was in operation from January 2014 until the end of 2017. It converted power from wind turbines into transportable, storable hydrogen using a new, specially developed electrolysis process that responds very quickly to changing loads from a wind farm, and can economically produce high pressure of around 165 bar.

Società Gasdotti Italia S.p.A.

HyBRIDS

Project envisages construction of a 2 km hydrogen pipeline and facilities connecting Green H2 production plant of Società Chimica Bussi (SCB) to SGI high-pressure gas network. This connection will provide:

- H2 / CH4 blending services for grid injection of excess H2 production initially up to 1% (in vol.);

- H2 modulation/ storage services allowing retrieval of H2 from pipeline, hence operating as storage infrastructure for other SCB uses.

Contact: Antonio.serlenga@sgispa.com

GRTgaz

MosaHYc (Mosel Saar HYdrogen Conversion)

GRTgaz SA and Creos Deutschland GmbH are collaborating to create a 100% pure hydrogen infrastructure, connecting the Saar (Germany), Lorraine (France) and the Luxembourg border. This 70 km-long infrastructure will be capable of transporting up to 20,000 m³/h (60 MW) of pure hydrogen via retrofitted existing gas pipelines.

Contact: jeanmarc.brimont@grtgaz.com

GAZ-SYSTEM

Damasławek UGS

The project calls for the first hydrogen cavern to be operational around 2030. The location and geological conditions allow for the creation of a storage facility of key importance to the energy security of Poland and the construction of the entire hydrogen economy. The storage facility can ideally fit into hydrogen clusters that will be created around industrial centers as well as offshore and renewable energy storage facilities.

Gasunie

H-vision

H-vision is working to set up plants that will soon be supplying industry with low-carbon hydrogen. This unique partnership extends through the entire chain, and includes three refineries, electric power companies and a number of knowledge partners that collaborate to accelerate the development of the new network. The first plant, with a capacity of approximately 750 MW, will be completed by late 2026. A second hydrogen plant can increase the total capacity to over 1,500 MW. In partnership with, Deltalinqs, Air Liquide, BP, the Port of Rotterdam Authority, ONYX-Power Rotterdam, EBN, Equinor, Shell, Uniper, Royal Vopak and ExxonMobil.

Ontras

Hydrogen Region Lausitz

Hydrogen from a large-scale electrolysis shall be injected into the gas transmission network of ONTRAS. The energy will be commercially offered to reduce the CO2 footprint of private households. At later stages the hydrogen ratio in the gas supply of a community will be increased with the target of eventually switch to a 100% hydrogen.

Contact: ralf.borschinsky@ontras.com

OGE

GET H2 Nukleus

The GET H2 partners BP, Evonik, Nowega, OGE and RWE Generation want to jointly build the first publicly accessible hydrogen infrastructure. The GET H2 Nukleus project combines the production of green hydrogen with industrial customers in Lower Saxony and NRW. The approximately 130-kilometer network from Lingen to Gelsenkirchen will be the first H2 network in the regulated area with non-discriminatory access and transparent prices.

TEREGA

RINGS

Research on the Injection of New Gases into Storage facilities (RINGS) is a research and development partnership to study the behaviour of biomethane and hydrogen when mixed with natural gas in deep aquifers, with a view to storing them effectively. In partnership with Storengy / University of Pau / CNRS / Carnot Institute / SNAM (observer) / ENAGAS (observer).

Ontras

Energy Park at BAD LAUCHSTÄDT

Hydrogen is produced by a 35 MW electrolyser, which is directly connected to a wind farm. The pure hydrogen is stored in a nearby salt cavern. The transport between the underground storage and the end users for the hydrogen inside an existing industrial area is provided by a converted natural gas pipeline.

Contact: Eric.Tamaske@ontras.com