INNOVATIVE PROJECTS PLATFORM

Hydrogen

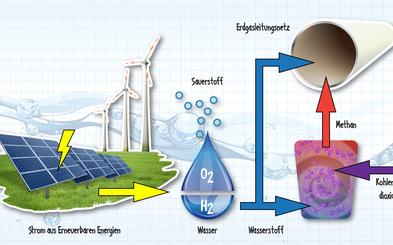

Hydrogen can be produced by various process technologies. Hydrogen can be obtained from natural gas through a steam reforming process or a methane pyrolysis process; produced by splitting water into hydrogen and oxygen via electrolysis or via gasification process, by converting solid fuel (coal or woody biomass) to hydrogen. Hydrogen can also by produced through anaerobic digestion, converting wet biomass to hydrogen. Hydrogen can be utilised directly as fuel or, depending on the application, blended with natural gas.

Hydrogen production from RES-based electricity in power-to-gas facilities or from other fuels in combination with CCS contributes to the decarbonisation of the energy system.

OGE

GET H2 TransHyDE

The central fundamentals for the reliable operation of a climate-neutral hydrogen infrastructure are now being further deepened with a view to the future - RWE, Nowega, Rosen, Evonik, the University of Potsdam, the DVGW, Adlares, Meter-Q Solutions and OGE are working on practical solutions for the transport of hydrogen.

OGE

SyWestH2

In the H2-suitability of steels project , materials that are currently used in Germany for the transport of natural gas are to be examined for their suitability for hydrogen. Random fracture mechanical tests should be carried out to check the steels used. The determined characteristic values are compared with the results on which the American regulations ASME 31.12 are based. The transferability of the ASME standard to the steels used in Germany is then validated. In partnership with Materials Testing Office (MPA) Stuttgar, DVGW

OGE

Westküste 100

This project is about creating a regional hydrogen network on the basis of a 30 MW electrolysis plant connected to the grid of a municipal utility. The end-to-end hydrogen value chain will include industrial customers, a hydrogen filling station and end users supplied by the municipal utility.

OGE

Zukunft RuH2r

Zukunft RuH2r aims to create the infrastructural conditions for the provision of hydrogen to decarbonize regional industry between the Ruhr metropolitan region and South Westphalia. Together with the project partners ENERVIE, Vernetzt and Westnetz, the project partners are pursuing the establishment of demand clusters and an expansion of the hydrogen cluster into the neighboring regions.

Nowega

GET H2

The strategic goal of Get H2 is to combine regions with a high share of renewable energies from wind and solar sources with H2 production on an industrial scale. The focus is on the development of a nationwide H2 infrastructure with the coupling of all sectors.

Contact: presse@nowega.de

Gaz-System

HESTOR- Energy storage in the form of hydrogen in salt caverns

The aim of the HESTOR research and development project carried out by a scientific and industrial consortium was to investigate the possibility of hydrogen storage in salt caverns, generated from RES, and its further use for energy generation and technological purposes in oil & refinery industry. The Project also considered technical and economic aspects of the use of hydrogen as a fuel in transport. Read more about the other issues addressed in the document using the link below.

Contact: dorota.polak@gaz-system.pl

GRTgaz

FenHYx

FenHYx is a first demonstrator on a European scale to test hydrogen and decarbonised gases in the networks.The FenHYx platform in particular aims to reproduce the features of gas networks and especially those of the gas transmission networks: compression, expansion, measurement, analysis, injection loop, etc. The opening up of this platform to other operators will contribute to the emergence of the hydrogen sector.

Contact: jeanmarc.brimont@grtgaz.com

Ontras Gastransport GmbH, SNAM Rete Gas S.p.A.

Linz Hydrogen Initiative

Austrian Presidency of the EU Council started the “Linz Hydrogen Initiative” and invited to a high level conference on the eve of the Informal Meeting of the Energy Ministers on 17 September. The conference focused on the topics of renewable hydrogen, energy storage technologies and innovative energy technologies for energy intensive industries.

Contact: ina.adler@ontras.com, dina.lanzi@snam.it

Enagás S.A.

RenovaGas

RENOVAGAS is a research project whose first phase finished in 2017. It first aim was the development of a 15 kW demonstration plant for the production of synthetic natural gas (SNG) from the electrolytic production of hydrogen with renewable energy sources (RES) and its combination directly with a biogas stream, that is, without separating CO2 from the methane, through a methanation process, so the synthetic natural gas obtained was fully renewable.

Contact: jrubio@enagas.es

Gas Connect Austria GmbH

Wind2hydrogen

The Wind2Hydrogen pilot facility in Auersthal, Lower Austria was in operation from January 2014 until the end of 2017. It converted power from wind turbines into transportable, storable hydrogen using a new, specially developed electrolysis process that responds very quickly to changing loads from a wind farm, and can economically produce high pressure of around 165 bar.

Contact: robert.paulnsteiner@gasconnect.at